Your Steel Building Specialist

Red Iron Steel

Red Iron Steel: What is It and What Makes it Different?

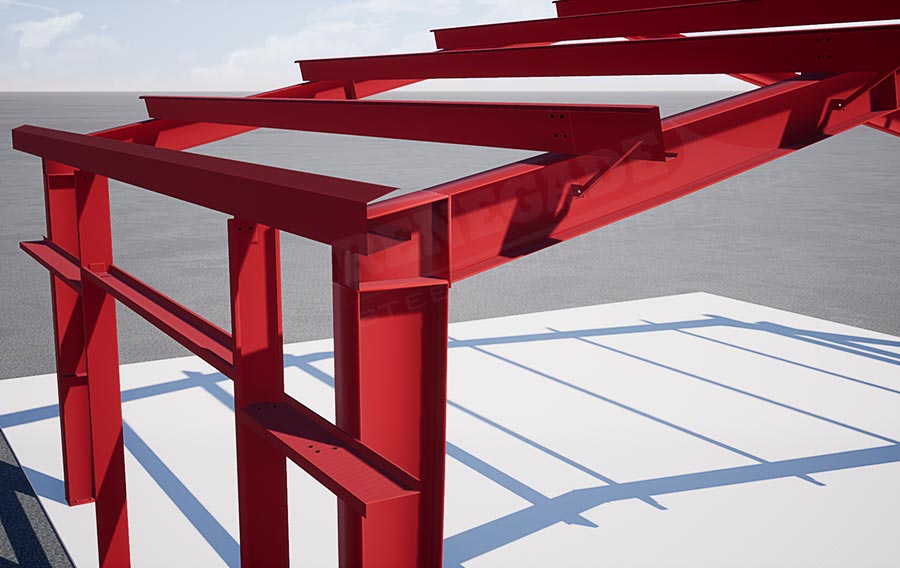

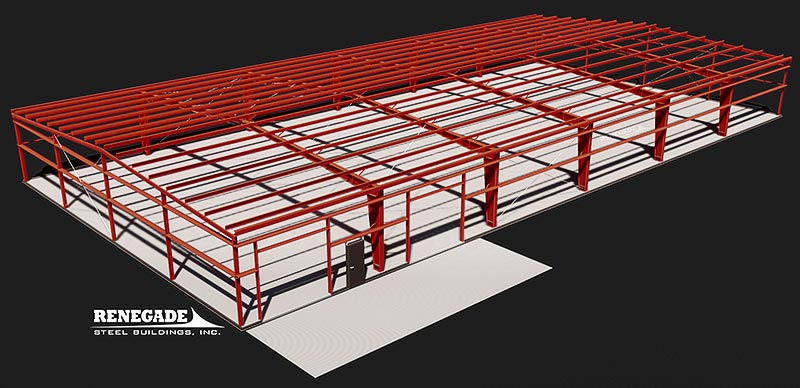

At a Glance: Red iron steel refers to structural steel I-beams that have been coated with a red iron oxide primer to prevent rust and corrosion. This building material is the backbone of pre-engineered metal buildings (PEMBs), offering exceptional strength, design flexibility, and long term value that traditional construction methods simply cannot match.

If you've ever driven past a large warehouse, manufacturing plant, or agricultural barn and noticed the bold steel frame taking shape, you've likely seen red iron in action. But what exactly is red iron, and why has it become the go-to choice for everything from backyard workshops to sprawling commercial storage facilities? Understanding this building material can help you make an informed decision about your next construction project.

The Origins of Red Iron Steel

The term "red iron" comes from the distinctive reddish-brown primer coating applied to structural steel during the manufacturing process. This primer contains red iron oxide, a pigment paste that serves as the first line of defense against rust and environmental factors. The red oxide coating has been used in the steel industry for decades because of its proven ability to protect raw material from corrosion before and during construction.

Structural steel itself emerged as a dominant building material in the late 19th century, transforming how we approach construction projects. The development of the Bessemer process made steel production more efficient and cost-effective, opening the door for widespread use in buildings, bridges, and infrastructure. Over time, engineers discovered that coating steel with red iron oxide primer provided excellent protection during shipping, storage, and the construction phase, giving rise to the "red iron" terminology we use today.

What Makes Red Iron Different from Other Steel Products?

When comparing red iron to alternatives like cold-formed steel home kits or steel or aluminum tubing, the differences become clear. Red iron steel consists of plates of steel welded (commonly called "built up") and hot-rolled structural steel that is shaped into I-beams, H-beams, and other heavy-gauge components while the metal is still heated. This process creates members with exceptional strength and load-bearing capacity that lighter-gauge materials simply cannot achieve.

Here's how red iron compares to other common construction materials:

- Cold-formed steel is made by bending thin sheets of steel at room temperature. While useful for certain applications, it lacks the load-bearing capability needed for larger steel structures.

- Steel tubing provides decent strength but doesn't offer the same structural integrity as solid I-beam construction for primary framing. In some cases the tubing is made from Aluminum.

- Wood framing remains popular for residential construction, but it's susceptible to rot, termites, fire, and warping that steel resists naturally.

The key distinction is that red iron steel provides the structural strength required for clear-span construction, meaning you can create wide-open interior spaces without interior support columns. This design flexibility makes red iron the ideal choice for warehouses, riding arenas, manufacturing plants, and any building project where unobstructed floor plans matter.

RED IRON COMPARED

Why Red Iron is the Preferred Choice for Pre-Engineered Metal Buildings

Pre-engineered metal buildings have become a popular choice for commercial, agricultural, and residential applications, and red iron is the reason why. When engineers design a PEMB, they calculate exactly how much steel is needed to meet local building codes and withstand expected snow loads, wind pressures, and other environmental factors. Every component is manufactured to precise specifications in a controlled factory environment.

The benefits of using red iron in pre-engineered steel building kits include:

- Superior load-bearing capacity: Red iron I-beams can span great distances while supporting heavy roof systems, overhead cranes, and mezzanine levels without structural damage.

- Clear-span structure capability: Buildings can easily reach widths of 200 feet or more without interior columns, maximizing usable space for operational efficiency.

- Resistance to pests and decay: Unlike wood, steel doesn't attract termites or rot over time.

- Fire resistance: Red iron steel won't ignite, providing better protection for your investment.

- Long-term durability: With proper maintenance, a red iron building can last for generations.

These advantages explain why red iron has become the best option for anyone seeking a building that will stand up to wear, weather, and time.

Understanding the Investment: Material Costs and Value

Some buyers hesitate when they see the initial cost of a red iron steel building compared to similar limited sized pole barns or tube-frame structures. However, evaluating the total cost of ownership tells a different story. Red iron buildings require less maintenance over time, resist damage from environmental factors, and maintain their structural integrity for decades. When you factor in insurance savings, reduced repair costs, and longer lifespan, red iron often proves more economical over the long term.

The supply chain for structural steel has also become more stable and predictable than many other building materials. Steel is one of the most recycled materials on the planet, and modern manufacturing plants have refined their processes to deliver consistent quality while managing material costs effectively. This reliability helps keep your building project on schedule and on budget.

WHAT IS RED IRON?

Structural Steel I-Beams and secondary members with red iron oxide primer for rust protection.

Why Builders Choose It

Common Uses

Why it Matters

Why it's Red

Applications: Where Red Iron Buildings Shine

Commercial and Industrial Uses

- Warehouses requiring massive clear-span interiors for inventory storage

- Manufacturing plants that need to accommodate heavy equipment and overhead systems

- Retail strip centers that benefit from design flexibility and quick construction

- Auto service centers requiring wide door openings and open work bays

Agricultural Applications

- Equipment storage buildings that protect valuable machinery from the elements

- Livestock barns designed for animal comfort and easy maintenance

- Hay storage structures that resist moisture and pests

- Riding arenas with column-free interiors for safe horse training

Residential and Recreational Projects

- Workshop buildings for hobbyists and craftsmen

- Garage structures for vehicle and equipment storage

- Barndominiums that combine living space with functional workspace

- RV storage and recreational buildings

The Construction Process: From Kit to Completed Building

When you purchase a red iron building kit, you receive a complete package of pre-engineered components designed to fit together precisely. The steel structure arrives with all main frame columns, rafters, secondary members (purlins and girts), and hardware needed for assembly. Wall panels and roof panels, typically made from 26-gauge steel or heavier, complete the building envelope.

Construction (Not by Renegade) typically follows these steps:

- Foundation preparation: (A concrete slab or pier foundation is poured according to engineered specifications.

- Main frame erection: Red iron columns are anchor-bolted to the foundation, and rafters are connected to create the primary structure.

- Secondary framing: Purlins and girts are attached to provide support for the wall and roof panels.

- Panel installation: Metal panels are fastened to the secondary framing to enclose the building.

- Accessories and finishing: Doors, windows, trim, and other components complete the project.

This straightforward process typically takes far less time than traditional construction methods, getting you into your new space faster.

Choosing the Right Partner for Your Red Iron Building

The quality of your red iron building depends heavily on the manufacturer and supplier you choose. Look for a company that provides certified, American-made steel that meets all relevant building codes. Transparent pricing, detailed engineering documentation, and clear communication throughout the process are signs of a trustworthy supplier.

Be cautious of vendors offering unusually low prices or using high-pressure sales tactics. In the steel building industry, you typically get what you pay for. Investing in quality steel and working with an experienced team will pay dividends throughout the life of your building.

Build with Confidence: Choose Renegade Steel Buildings

Now that you understand what is red iron and why it matters, you're ready to move forward with your building project. At Renegade Steel Buildings, we specialize in custom, pre-engineered red iron steel building kits designed to your exact specifications. Our team provides honest pricing, clear documentation, and straightforward support from your first quote through delivery.

We believe in doing things differently. No pushy sales tactics. No hidden fees. No surprises. Just quality American-made steel buildings backed by experience and integrity.

Ready to start your building project? Explore our building options, use our 3D building designer to visualize your project, or request a quick quote today. Let Renegade show you the difference that quality and transparency can make.