Your Steel Building Specialist

Steel Buildings are the most versatile, durable and economical type of construction. Today’s steel buildings are often even combined with more traditional construction materials such as masonry, glass, siding and other exterior options to create about any appearance needed. More advantages of a Pre-engineered Steel Building include:

![]() Faster and more economical than conventional construction. Steel buildings are pre-fabricated at the plant making for quicker installation and lower labor cost.

Faster and more economical than conventional construction. Steel buildings are pre-fabricated at the plant making for quicker installation and lower labor cost.

![]() Engineering to meet specific wind and snow load requirements.

Engineering to meet specific wind and snow load requirements.

![]() Fire, hail and termite resistant.

Fire, hail and termite resistant.

![]() The ability for wide spans with no interior columns.

The ability for wide spans with no interior columns.

![]() Ease of future expansion or changes to the exterior appearance.

Ease of future expansion or changes to the exterior appearance.

Renegade is the right choice!

Renegade’s Steel Buildings are used for virtually any type of commercial, agricultural or industrial application. Our Steel Buildings are designed to meet the highest design requirements in the industry and all are framed with 100% red iron top grade steel and sheeted with high tensile 26 gauge panels. All our buildings ship pre-cut, stamped and piece marked for easy on site construction. We stand behind our product and offer a 25 year warranty.

Structural Design

Renegade offers all standard structural designs and frame types (as shown below) as well as custom structural designs to best suit your needs. Our dedicated and experienced staff will determine the most efficient and cost effective design for you based on your overall needs such as interior clearances, architectural concerns, etc. Here is a brief outline of the structural components of your Renegade Steel building; this information can be helpful when reviewing your building quote as well. Standard “main frame” spacing also known as bay spacing is typically between 20’ and 25’ but other more custom designs can accommodate up to 40’ between main frames. The most commonly used endwall frames are “bearing frames” (1/2 the load of a main frame), although main frames are also used on endwalls for various reasons such as future expansion, bracing or open endwall conditions greater than 30’. Standard bracing options consist of “cable” or “rod bracing”, “fixed base columns”, and “portal frames” also known as “wind bents”.

Renegade prides itself on providing IAS Certified buildings. The International Accreditation Service (IAS), a recognized accreditation body in the United States since 1975, is a non-profit, public benefit corporation. IAS accreditation is internationally recognized as a mark of consumer confidence and product quality. All of our manufacturing facilities are also members of the Metal Building Manufacturer’s Association (MBMA). MBMA provides engineering leadership through sponsorship of research programs used to improve the performance, efficiency and quality of metal building systems.

Renegade makes it easy to purchase a quality Steel Building. Our building specialists will take your initial concept and develop the perfect design to best accommodate your needs.

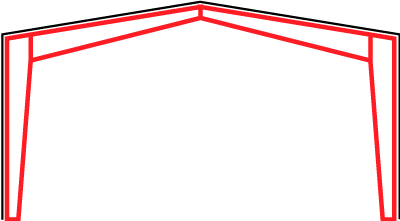

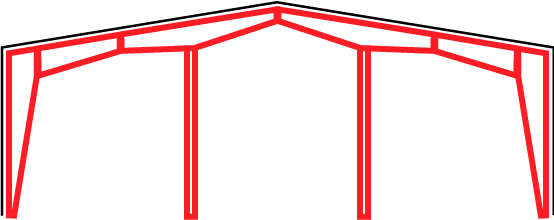

Clear Span Gable

The standard style clear span red iron steel building consists of tapered steel frame members resulting in an economical and sturdy structure for your steel building.

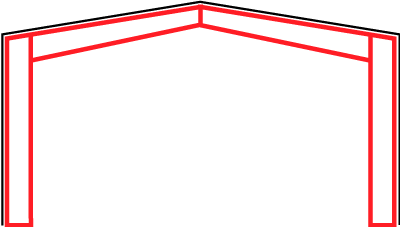

Straight Column Gable

The straight column clear span red iron steel building is engineered with maximum interior design and build out in mind.

Modular Span Gable

This design utilizes both solid framing and interior support columns to allow for wider over all widths that could be allowed by clear span alone. Can be designed with 1, 2 or 3 rows of columns.

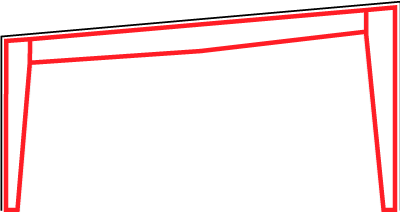

Clear Span Single Slope

Similar to the standard style with tapered steel frame members but with a single slope resulting in a high side and low side to the building. This design is very popular in the retail building environment.

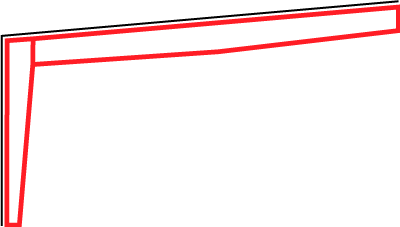

Lean To Single Slope

Similar to the single slope with tapered steel frame members but a high side to be supported by an existing wall designed to carry the additional load.

Renegade Steel Buildings Standard Features

More than a basic building

"Long Life" Fasteners

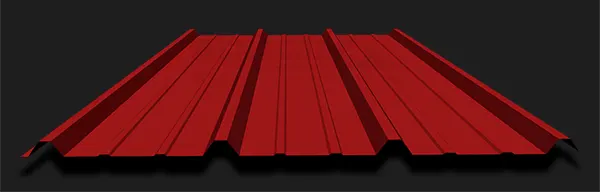

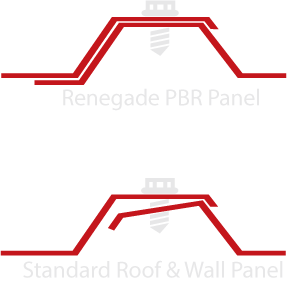

PBR Panel

Bearing Rib Panel

Renegade uses the "PBR" panel standard on the roof and walls of all our buildings. The purlin bearing rib feature gives the system rigidity and complete weathertightness. Other standard panel profiles are available and all have the purlin bearing system.

Our competitors often use the standard panel on the roof and walls. Not having a "purlin bearing rib", this system creates a void in the lap thus making it less rigid and less weathertight.

Renegade specs framed openings for all windows

Self Flashing Window

There are a couple of ways to install a window in a steel building. The "cheapest" way is to just cut an opening and screw the window frame to the wall panel. The problem with this method is that there is nothing to keep the wall panel from flexing and working the screws and seal loose on the window. Essentially the window is just floating in the wall panel with no other support.

Window with Framed Opening

The best way to install a window in a steel building is to add a framed opening to support the windows and wall. This gives the window frame a solid structure to attach to providing a structurally sound installation. Another benefit of the framed opening is having structure to attach to if you add liner panels or decide to add any kind of wall panels to the inside of your building.

When you buy a window from most steel building companies, all you get is the self flashing type with no red iron added for support. With a Renegade building, we will typically quote a framed opening to support your windows. The difference is clear, we provide you with a quote on a building configured just like we would want if it were our own.

Base Trim

You may be saying to yourself, "what is base trim, and why do I care?" Hopefully the illustrations below will help you see and understand the differences in base trim on a steel building and why we feel formed base trim is the best option.

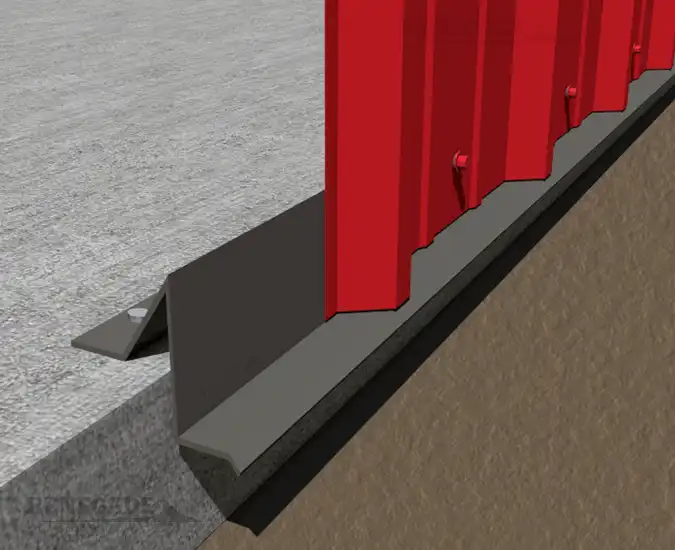

Formed Base Trim

This is a "Premium" trim that we include on all our buildings. The concrete is poured with a squared off edge and the formed base trim is attached around the perimeter. The wall panel then attaches to this 1 piece system.

As you can see in the cutaway portion of the illustration, there is no screw behind the panel. The formed base trim is also a thicker gauge material than regular trim pieces.

While this "premium" base trim adds little cost to your building many companies still don't use even though it is truly the best option for your building!

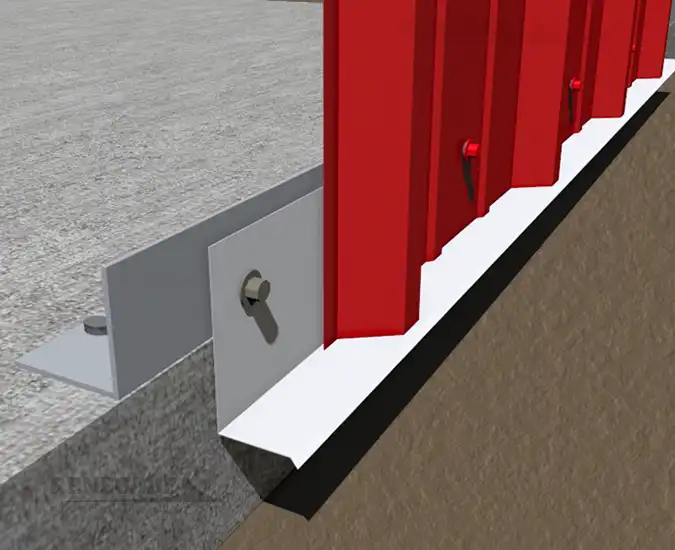

Base Angle with Flashing

This is a common style still used today by many companies. The concrete is poured with a squared off edge with angle iron attached to it. A second piece of thin base trim is attached to the angle iron. The wall panel then attaches to this 2 piece system.

While this method works OK, there are some considerations to think about. First of all, it takes additional labor to install 2 pieces around the perimeter of the building. Second is that care must be taken to place the trim screws in the proper position or else the panel may be pushed out. As you can see in the cutaway portion of the illustration, there is a screw behind the panel. There is also the possibility that the panel lap screw could hit the mounting screw.

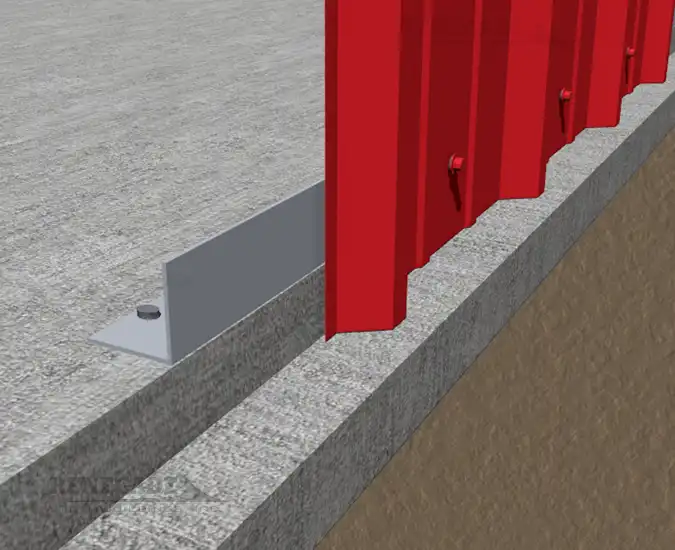

Concrete Notch with base angle

This is the old style of finishing the bottom of a building where you would create a notch in the concrete for the panel to rest against. As you can see from this illustration, your concrete contractor would create a 1.5" x 1.5" "notch" at the outside edge all the way around your concrete pad. Angle Iron is attached and the panel is secured to the angle.

This method required more work and cost in your concrete. It also ended up being a prime location for rust to corrode your building as often times the notch would hold water against the bottom of the panel.