Your Steel Building Specialist

Metal Building Kits – Did You Know…

Metal Building Kits - Did You Know...

Did you know...

Not all Metal Buildings are the same

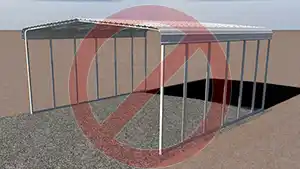

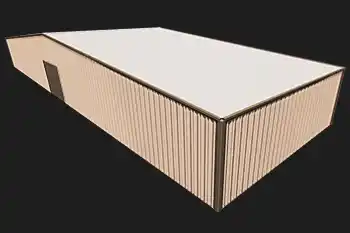

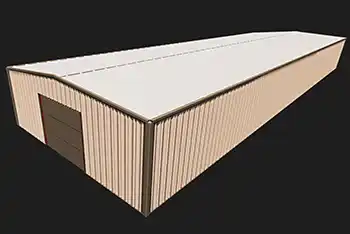

Many companies and people in general refer to a wide variety of buildings as a metal or steel building. This can range from a red iron steel building like what we sell, to wooden pole barns covered with thin metal panels, arch style quonset huts, and even tube frame style carports. Each of these type buildings has their place in the market at different price points.

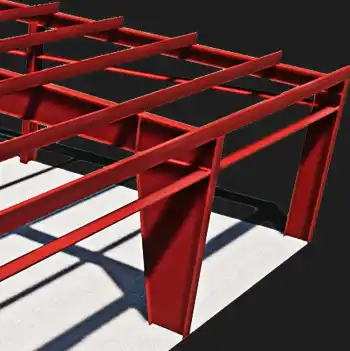

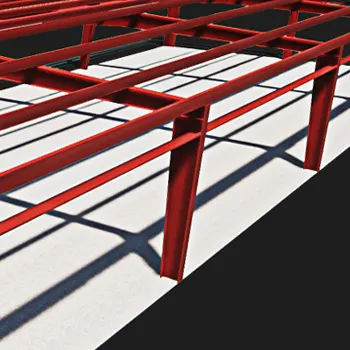

The only type building that Renegade Steel Buildings sells is a commercial style I-beam main frame building. This is often referred to as a pre-engineered or pre-fab steel building. Our Metal Building Kits are bolt together and come with engineer stamped metal building plans. This type building allows you to have clear span designs to accommodate any floor plan or layout for office space, equipment, racking, automotive lifts and more.

Ultimately steel buildings are sold based on weight. With that in mind a building that is all steel will cost more than one that is framed in wood or supported by aluminum tubes. With that higher price also comes added strength and rigidity as well as lower or no maintenance costs.

Sold by Renegade

Metal Building Kits come with most everything you need

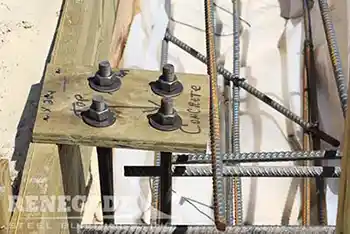

Now you may be saying to yourself "Why doesn't the kit contain EVERYTHING I need?" There are some legitimate reasons why there would be items that are not included. One of the first things to know is that Anchor Bolts are not included with your kit. Anchor bolts are part of your foundation and are different lengths depending on the area that you live. In the Southern US the bolts required may be 18"-24" but as you move further north into areas that have frost line depths you might see the bolts range from 36"-48" or more. The bolts should also be placed when forming and pouring your concrete so you would need them before your building would arrive.

Did you know that the engineered plans include anchor bolt plans but not foundation plans? That's right, the anchor bolt plans provide information about where the bolts are placed, the pattern for the base plate and the diameter of the bolts. All of these details come from the structural engineer for your building, but foundation plans come from a different engineer. If you need foundation plans, your concrete provider may be able to supply them. In some cases, we can offer foundation plans depending on your area.

Wood blocking is often needed when erecting a steel building. If you hire a company to erect your building, they most likely have the blocking needed to support things like wall girts until the wall sheets are added. These are simply items that are used during the construction of the metal building kit and can be discarded once complete.

This is not a comprehensive list, but is just a few of the general items that you may need to consider in your overall budget.

Standards make metal building kits different

Have you looked at several websites or even received a couple of quotes, you may be asking yourself, "What's the difference in these buildings?". Other than knowing if your getting a red iron I-beam building verses a tube frame, some of the differences are in the standards. While any company can sell you a building, we at Renegade like to offer you a building that we would want in our own back yard. In fact, several of us do have a Renegade building or two on our property. We specify standards for all of our buildings that other companies may not.

One of the most important standards we have is long life fasteners on the roof and walls. These screws come with a neoprene washer that helps protect your PBR panel and the finish warranty. Next up is the formed base trim we spec at the base of the building. We feel this is the best and easiest base trim to use. These are just a couple of the standards you can expect to find on a Renegade Steel Building.

Some metal building designs are more economical than others

Economy in design

Everyone knows the bigger a building is the more it costs, but did you know there are ways to design a building that can result in cost savings? That's right, we are usually looking for ways to help save our customers money. Lets look at a few ways we can value engineer a steel building.

First and foremost, the clear span width of a building should be smaller than the length of a steel building. There are cases where this may not fit such as aircraft hangars, but in general, this is the most practical way to setup a metal building. Keeping the width of the clear span rafters as short as is needed helps minimize the design needed for the size of the I-Beam required. The length of the building is accomplished by simply adding more frame lines and bays to reach the desired specs. Since steel buildings are priced according to the weight of steel involved, it is always good to consider how the heaviest pieces such as the I-beams are designed.

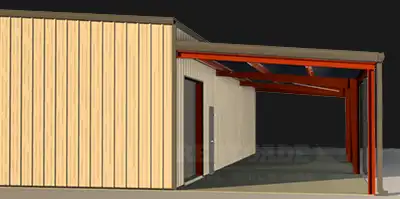

Steel Building Lean To

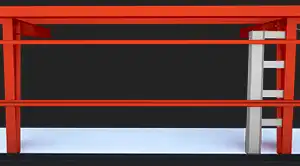

Steel Building Bracing

Steel Buildings Utilize Recycled Steel

Did you know that steel is one of the most highly recycled materials you can work with. In North America alone, more than 80 million tons of steel are recycled annually. In fact, many of the components of your steel building may contain recycled steel.

If your concerned about sustainability, your steel building fits in the cycle well. Steel products can be recycled over and over with no detriment to strength. Your building that is made with recycled materials is also recyclable. This helps to make your building environmentally friendly.

Beyond that, a pre-engineered steel building creates less waste than conventional building materials. With the entire building being fabricated to exact specs, waste material is cut to a minimum. Those waste materials are recycled again to make more steel products. Just consider the amount of materials that go into a dumpster on a typical wood frame job site.

Steel Building Barndominium

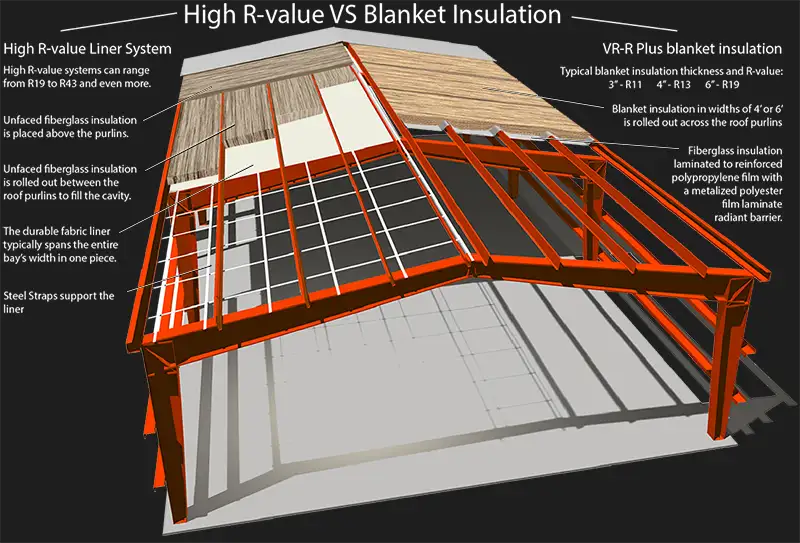

Insulation and energy conservation codes in a steel building

Were you thinking of heating and cooling your building or possibly even living in it? If so, you may not know that many states have energy conservation codes for your building that you must meet. While those codes can significantly increase the amount of insulation you will need (along with the cost as well), the additional insulation can result in greatly reduced energy consumption and a shorter Return on Investment than expected.

Utilizing a liner system for insulation affords you the ability to achieve high R value insulation ratings along with a clean finished appearance, reduced HVAC costs and energy code compliance. You may even qualify for various incentives from local, state and federal governments as well as local utilities for achieving certain energy efficiency targets.

Steel Pricing

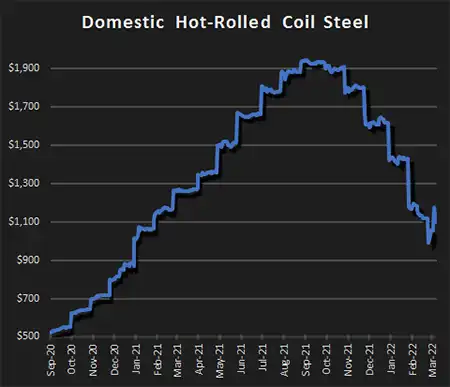

Over the last few years, we have all seen the huge fluctuations (mostly increases) on all building materials. From raw materials through finished products, prices have risen incredible amounts. Speaking of steel specifically, we saw raw material prices increasing starting in 2020 and steadily climbing to a peak around the summer of 2021. Since then, it has slowly decreased. So you may be thinking "why haven't metal building kit prices come down?" The answer still goes to supply and demand. Even as the steel commodity prices have decreased, the demand for steel in many industries has remained high.

For instance, delivery times were around 8 weeks just a few years ago. At one point last year, it was taking nearly 40 weeks to deliver a building. The number of jobs and the amount of steel to complete those jobs filled up the capacity of the manufacturing facilities. When the demand is as high as it has been, the only way for plants to control production is with pricing. Since we have seen the price of commodities like domestic hot-rolled Coil Steel come down, and we are beginning to see the back side of those longer delivery times, we hope to start seeing the pricing and delivery estimate improve over the next 6-9 months.

Deals too good to be true

Have you ever heard the phrase, "it's unwise to pay too much but it's also unwise to pay too little"? Of course nobody wants to pay too much for anything, but getting a quote for a steel building that is way under priced compared to all the others should be a red flag. It pays to be cautious of anything that just seem to be too good to be true. Usually there is a difference in the building. It may be a different type building like one of the ones listed above. It could be designed differently or maybe even missing some design elements. When you look at a Renegade Steel Building quote, everything that is included with your building is specified. When you look at our bottom line, that is your total. Some companies don't include tax in their total and just add it to your COD amount so that their "bottom line" appears to be less.

Not sure if your comparing apples to apples? We can help you go through comparing quotes to make sure your getting what you expect at the price you expect. Let us help you make the best buying decision to decide who you want to buy a steel building from.