Everything you need to know about buying a Steel Building

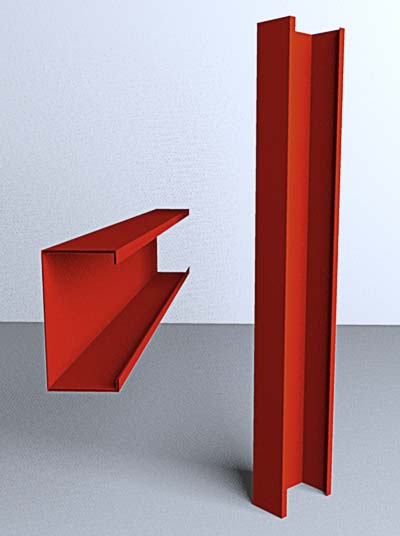

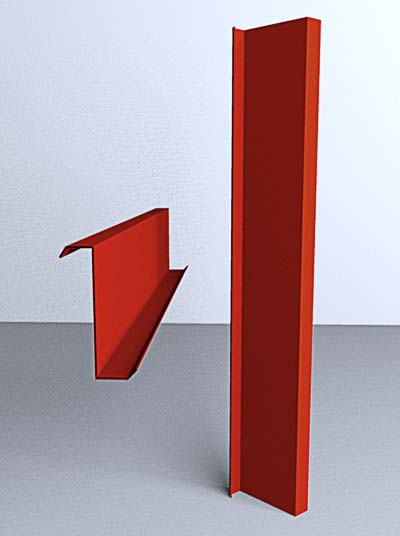

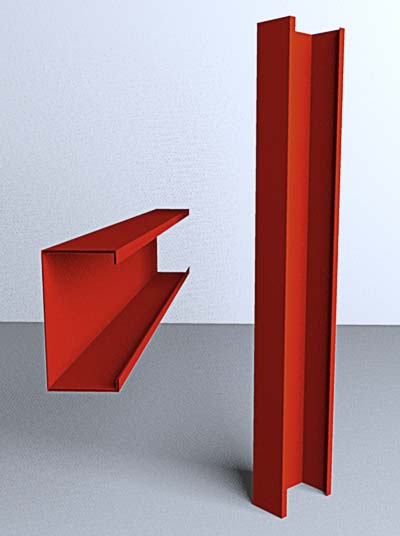

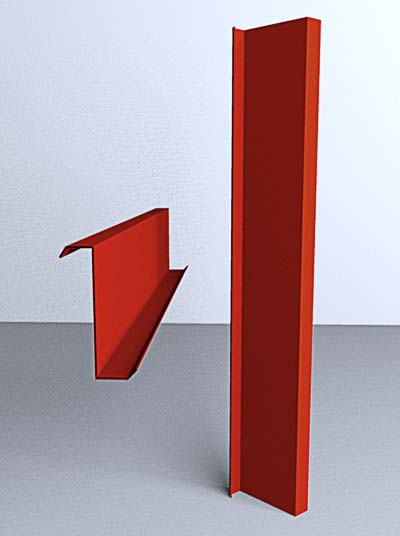

We understand how difficult it can be wading through all the companies out there selling steel buildings. In fact, there are many different types of steel buildings to choose from. What we are here to help you with specifically is pre-engineered steel buildings, also known as "Red Iron" steel buildings. Unlike other buildings that may look similar, the framing of a pre-engineered steel building utilizes I-Beam steel for the main support of the building and steel "Cee" and "Zee" components for the secondary support, then clad with steel panels. This is the type of building that we supply.

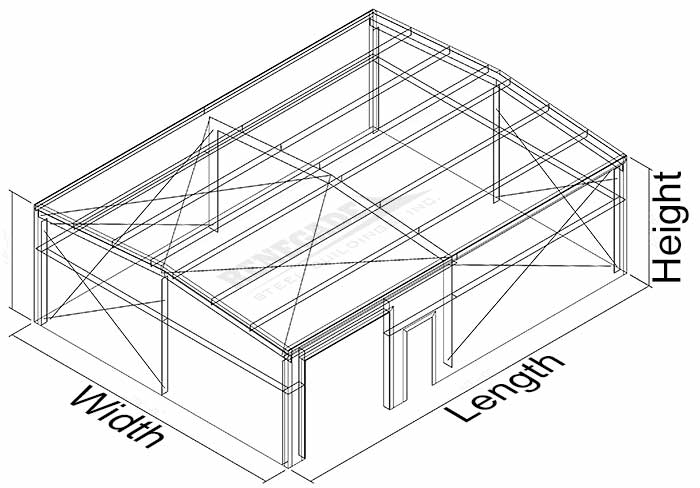

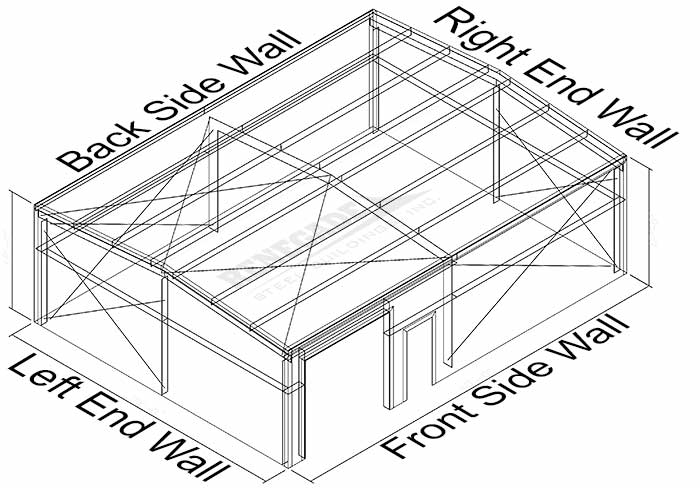

To get started working on a quote for a Renegade Steel Building, there are a few pieces of information we need to know. First up is the Width, Length and Height of the building you want. Typically the width is on the gable end of the building, the length is on the side where the gutters are located and the height is the measurement at the eave. Another vital piece of information is the zip code for the location where the building will be located. The zip code gives us the default values for wind, snow and seismic loads for a building in your location. We use these values to setup the engineering requirements for your building. We still encourage our customers to verify their code requirements with the local municipality as some areas may specify different loads.

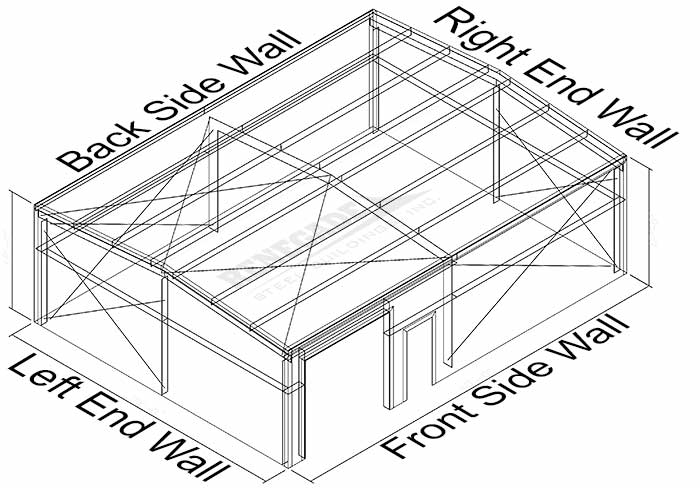

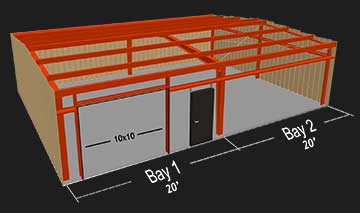

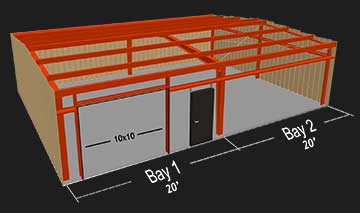

After getting the basic info for your building, we want to know what size doors you want and where they need to be located. In order to place openings in the correct place, we refer to walls as indicated on this illustration. This is the way the walls are setup in the metal building software. When we have completed your quote, we also typically include a 3D sketch much like this so that you can visualize everything on your building.

Last, but not least, we need to know the pitch you want for the roof of your building. The most common roof pitch for steel buildings is 1:12. Now you may be asking, what in the world does 1:12 mean. So the first number is the rise of the roof across the distance of the second number. On a 1:12 pitch, that means that the roof rises 1 inch for every 12 inches across the width of the building. In those terms, a 30' wide building with the peak in the middle would rise 15 inches from the eave to the peak.

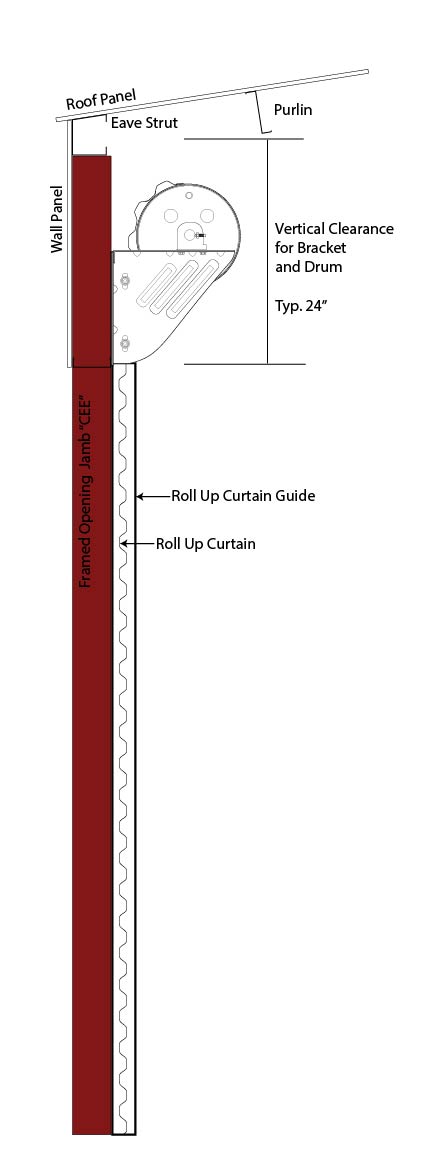

Now that we have the basic information needed to setup your building, we can get started working on your quote. There are a few other factors that may influence the design of your building. In fact, your project manager may ask a few questions about fitting certain aspects like door heights compared to the building eave height. There has to be enough room above a door opening for the track and drum to fit. For instance, a 10' tall door will need almost 2' of clearance above the opening to fit, so the eave height may need to be adjusted for it to fit.

If you take a moment to look at the door vertical clearance illustration, you can see that the brackets place the drum above the framed opening height. This gives you the full clearance of the opening while accommodating the curtain as it rolls onto the drum. The larger the door, there is more clearance required. While this illustration shows most of the considerations, there are other factors that can interfere with the opening and operation of the door whether it is a roll up or panel door.

That's why we like to have conversations with our customers so we can help determine the most economical way to configure your building while giving you the features you want on your building.

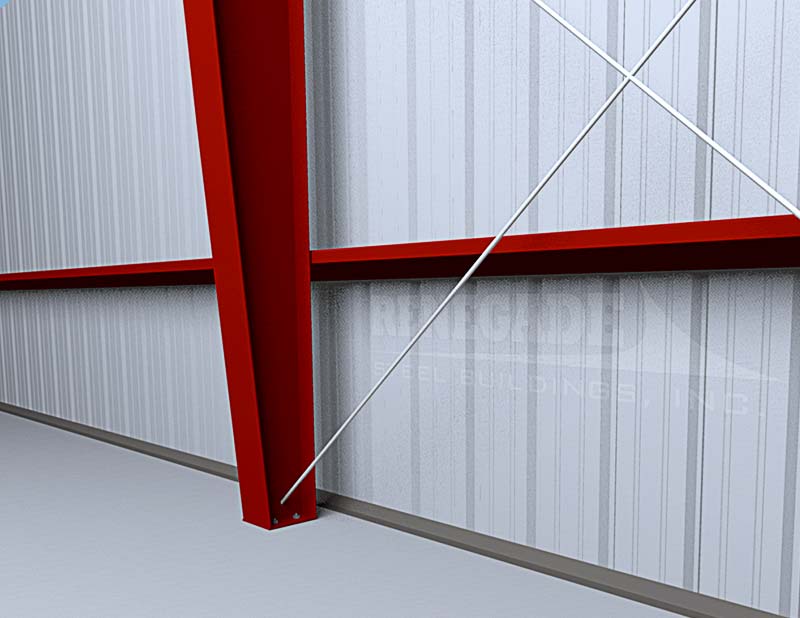

The next thing we have to consider is the bracing for your building. Every steel building requires bracing to counteract wind, snow and seismic loads. There are several methods to brace a building. We'll go into the most common here, and you can see more details on our

steel building bracing page.

The most basic way of bracing a building is with cables or rods that create an X between main structural members. This option is only available when there are no openings that it may interfere with.

X-bracing doesn't work when you have openings in a wall for doors or windows, so another method of bracing the building is required. Using a portal frame is useful in this case and provides the bracing needed along with providing space for openings. This method is more expensive as it uses actual steel I-beams to accomplish the structural requirement for the building.

Another method available to brace the building is called a wind column. This again allows more clearance for openings to be placed in a particular bay, but does come with some qualifications. Since the column transfers the load into the ground at a single location, the concrete pier requirements can be hefty. At times, though, this may be the only option available to be able to fit everything in that's needed.

Width, Length, Height, roof pitch, Location, and framed openings - Everything we need to calculate a price for a building, right? That information does give us most of what's needed to get a quote on a building. The bigger question is do we have everything setup how you want your building designed. While it may seem like this is all you need to get a quote, there are other qualifications and options for your building. Usually, a quick phone conversation about your building and how you want it designed can allow us to provide a more accurate quote. Let's jump into some additional options that you might want to consider for your building:

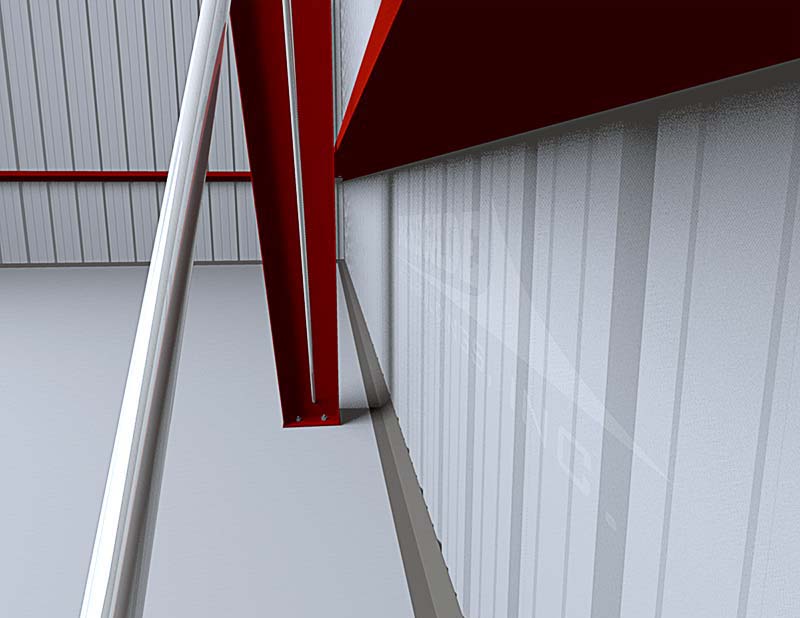

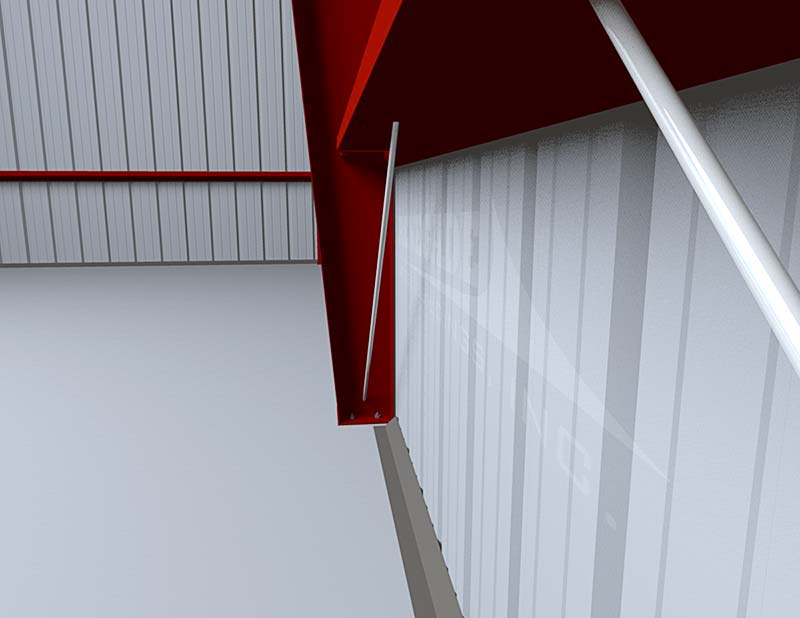

Bypass Girts run along the outside (or bypass) the I-beam column. This means that the base of the column is sitting back 8 inches from the outside edge of the concrete or what we commonly refer to as the steel line. The bracing used is set inside of the girts as well. This is typical for many of the buildings we do, but there are times when this may not work for your design.

Flush Girts run inline (or flush) with the I-beam column. This means that the base of the column is sitting flush with the outside edge of the concrete. The bracing is set inline with the girts as well. Using flush girts can help when there are going to be interior walls by reducing the amount of the column that needs to be boxed in.

Insulation

There are several products to insulate a steel building. One of the most popular is reinforced polypropylene laminated fiberglass insulation in 3" (R-10), 4" (R-13) or 6" (R-19) thick blankets. This insulation is installed between the wall panel and the girts, or the roof panel and the purlins.

For areas requiring a higher R-value, we can provide a two layer liner system to give you better insulating performance and long term energy cost savings.

For even more info, check out our steel building insulation page.

Custom Options

Some commonly asked for options to

customize your steel building are roof extensions and wainscot. Extensions certainly dress up a building but they can be more expensive than expected. Adding wainscot is probably the most cost effective way to dress up a building.

Bays and Spacing

A bay is the space between the frame columns. This can be between the main frame I-beam columns on the side wall or between the "Cee" columns on the bearing frame end wall.

"Cee"

"Zee"

Secondary structural members are used in a variety of places in the building.

"Cee" members are used for bearing frame walls (also known as post and beam) as well as framed openings.

"Zee" members are used for wall girts and roof purlins.

Roof Snow Load

Building Wind Load

Every building is engineered with wind, snow and seismic loads as prescribed by International Building Codes (IBC). These IBC codes utilize the specifics of each location to determine the design of the building. While we have guidelines to go by, it is important for each customer to check with the local permit office to verify what specific Code they require along with the wind and snow loads. Each municipality can require additional loads that may not be accounted without talking to them.

We try to give you as much info as possible so that you can be an educated buyer. This applies to not only the building but the entire

buying process as well. We simply want to help you get the best building at the best price and help you avoid high pressure and misleading practices by some of the other companies out there. That's why we specify everything on our contract so that you know exactly what your buying. On top of that, our bottom line is just that, no hidden fees, no extra costs added on later, just the total that you will pay for your building kit. Give us a call or fill out our Quick Quote form to get a price on your steel building. We are here to help.

Price your steel building