Your Steel Building Specialist

Steel Building Buying Guide

Steel Building Buying Guide

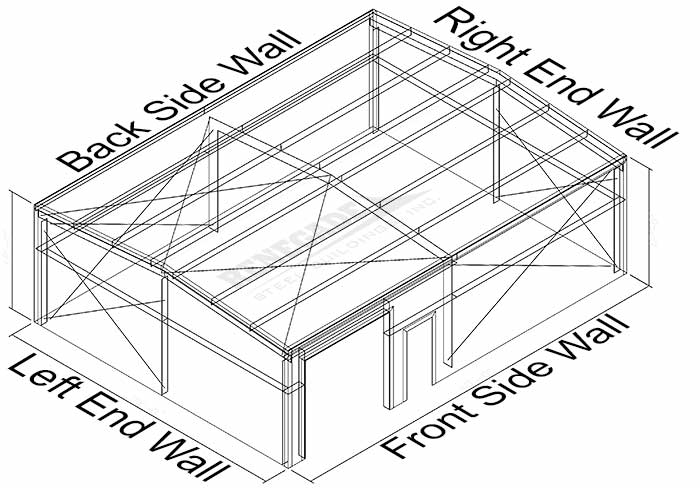

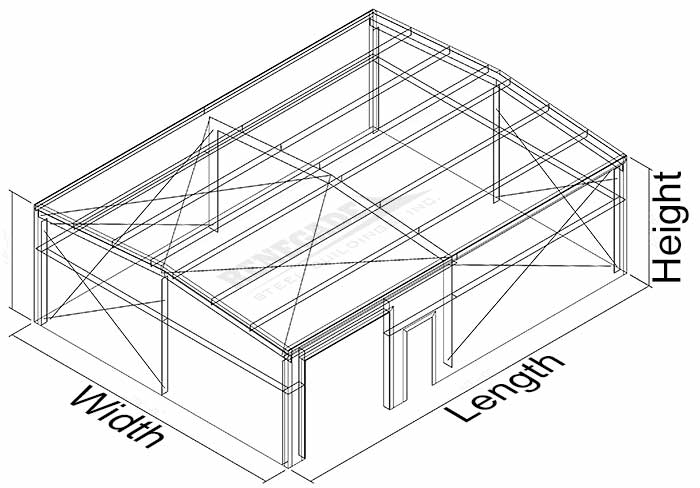

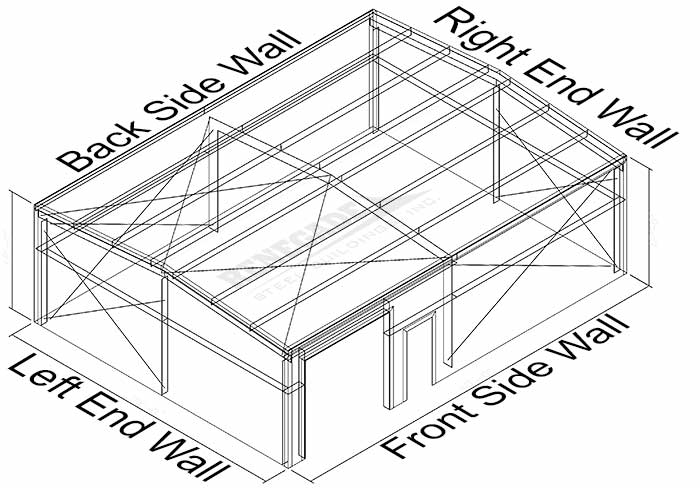

Steel Building Basics

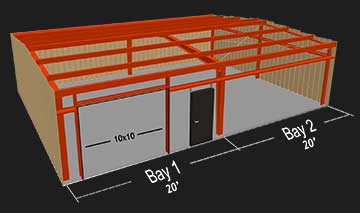

Things you need to know when buying a Steel BuildingPre Engineered Steel Building Dimensions

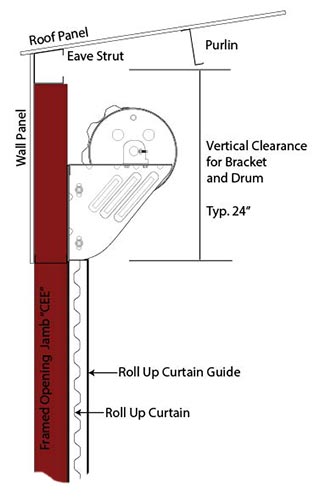

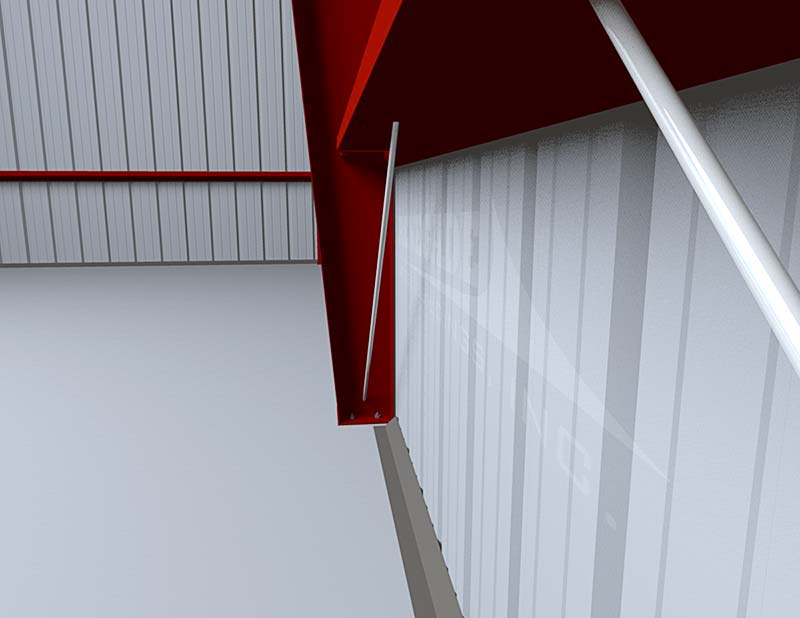

If you take a moment to look at the door vertical clearance illustration, you can see that the brackets place the drum above the framed opening height. This gives you the full clearance of the opening while accommodating the curtain as it rolls onto the drum. The larger the door, there is more clearance required. While this illustration shows most of the considerations, there are other factors that can interfere with the opening and operation of the door whether it is a roll up or panel door.

That's why our building specialists like to have conversations with our customers so we can help determine the most economical way to configure your metal building kit while giving you the features you want.

Steel Building Options

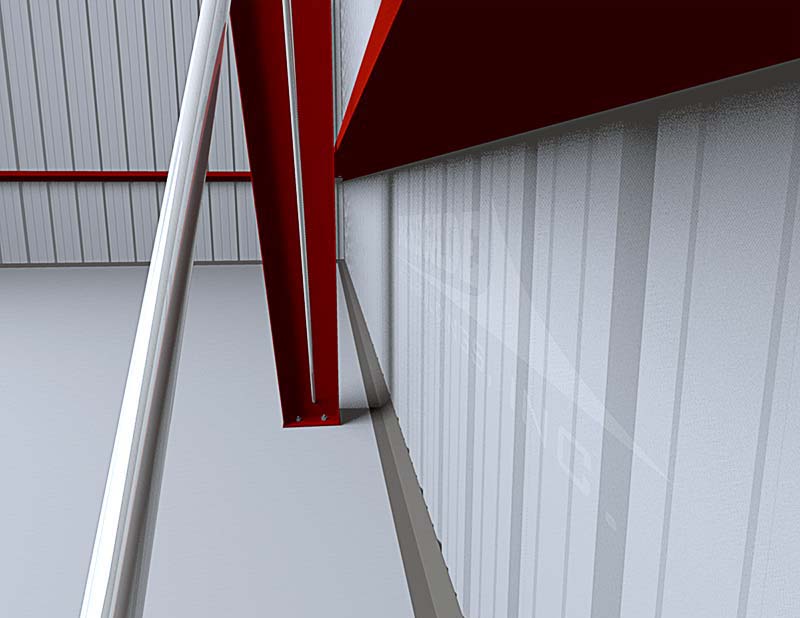

There are several products to insulate and increase energy efficiency. One of the most popular is reinforced polypropylene laminated fiberglass insulation in 3" (R-10), 4" (R-13) or 6" (R-19) thick blankets. This insulation is installed between the wall panel and the girts, or the roof panel and the purlins.

For areas requiring a higher R-value, we can provide a two layer liner system to give you better insulating performance and long term energy cost savings.

For even more info, check out our insulation page.

Steel Building Terms

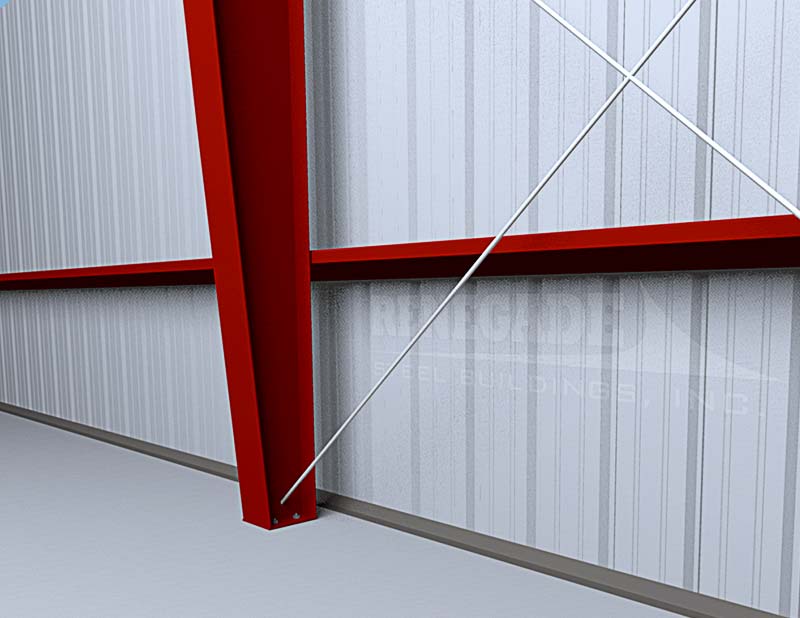

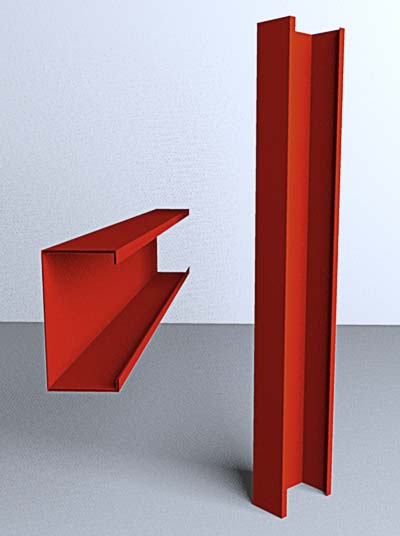

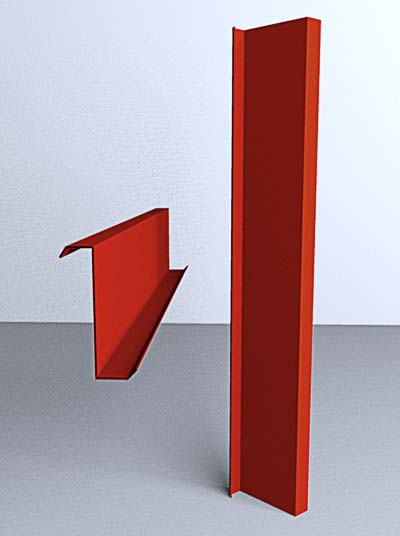

Secondary structural members are used in a variety of places.

"Cee" members are used for bearing frame walls (also known as post and beam) as well as framed openings.

"Zee" members are used for wall girts and roof purlins.

The Bottom Line

Property Line / Lot Setback

When you're thinking about what size is going to best fit your needs, you also have to consider what size will fit on your property. Most lots, whether residential or commercial, will have specifications for setbacks along the property line. In fact, in some residential areas, there may also be limits on the square foot size of the building in relation to the main dwelling on the property. For commercial properties, there may even be additional setbacks from road frontage and right of way to consider.

It's better to know up front any limitations to consider rather than running into problems down the road when you try to get your building permit. It's much easier to adjust the size when it's in estimating than if it has already been purchased. We strongly suggest checking your local requirements to make sure you can get what you want before you even start with site preparation.

Local Codes

Steel Building Suppliers

Company Culture

What do we mean by "Company Culture"? It comes down to how a company chooses to do business. Honesty and integrity is how the owner of Renegade does business. We strive to have an accurate quote that reflects everything you asked for including any specific needs. We also work just as hard after the sale to provide excellent customer service. At the end of the day, if there are any issues, we strive to resolve the issue quickly and proficiently to keep our customers happy.

While we can't speak for other companies out there, we can suggest for you to do your research. Some companies are quick to push for a down payment, others don't put the real total on their quote and some simply use sketchy sales tactics to get you to sign their quote then hit you with up charges after the fact. You won't find any of that at Renegade. What you will find is that we like to discuss what you want and need. We may even suggest ways to help value engineer your prefab metal building to get the best bang for your buck. We also want to make sure you are comparing apples to apples when looking at other companies.

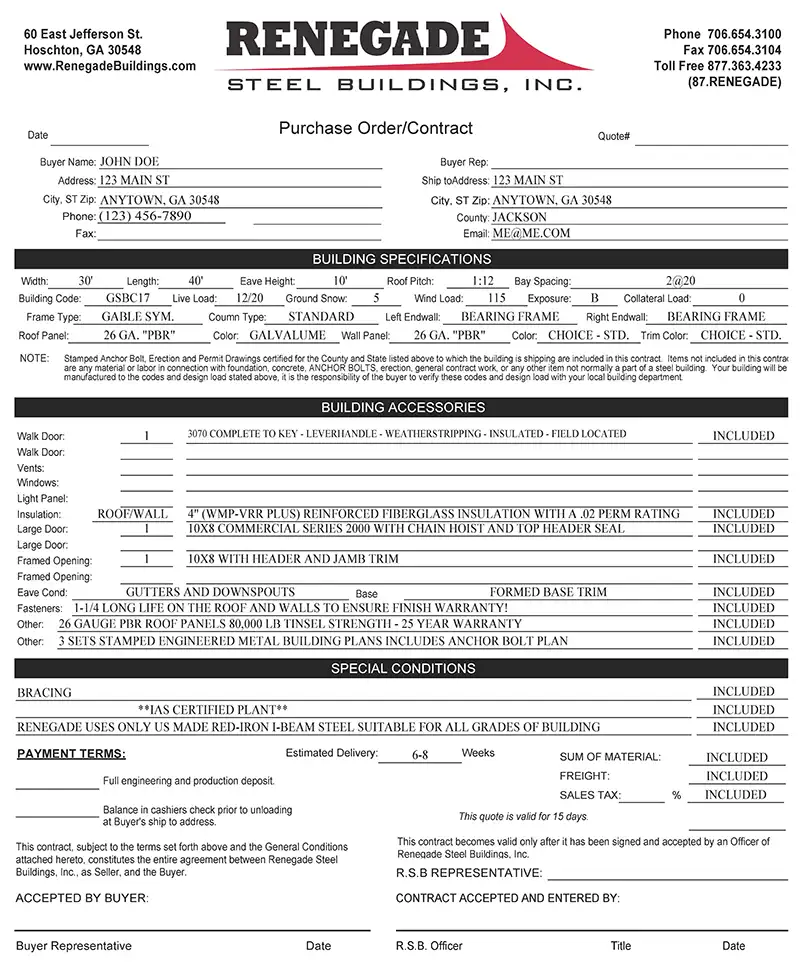

Your Quote

We put everything on our quote that you are requesting so that you know up front what you are getting for your money. We often talk to customers that are comparing quotes and they tell us that a salesman assured them they are getting something that is not listed on their quote. Since your quote becomes a legal contract once executed, what is listed is what you get, nothing more nothing less. That's why we specify clearly what options come with your prefab metal building.

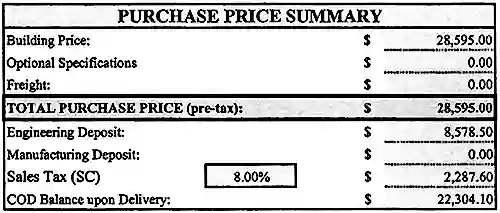

We also list our actual, real bottom line on our quote. When you see the total on our quote, it includes everything from shipping to tax and includes everything listed as included. Other companies show you a total price, but then you have to add engineering or freight and tax. So their "total" looks better, but their bottom line may cost you more.

Quote Comparison

Know who your talking to

Product Comparison

Certification

Standards

In years past, there were wide discrepancies for steel buildings. Some suppliers chose the cheapest materials possible to have the lowest price. Others would pick and choose a couple of standard items but go cheap on others. These days, much of the industry uses similar specs so we would like to share what standards are on a Renegade Building.

- 26 Ga PBR Panels

- Formed Base Trim

- Optional two piece base trim for additional colors

- Framed openings for Windows

- Long Life screws in the roof and walls

- I-beam steel frame

- Fabricated in the United States