Your Steel Building Specialist

Understanding the Benefits of Pre-Engineered Metal Buildings (PEMB)

Understanding the Benefits of Pre-Engineered Metal Buildings (PEMB)

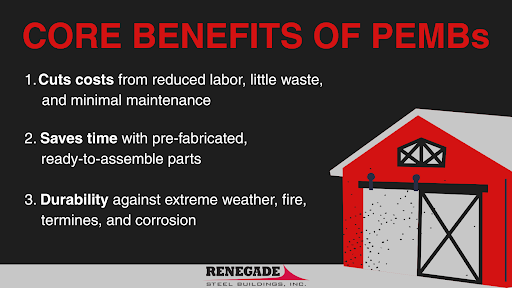

The Short Answer: Pre-engineered metal buildings (PEMBs) are custom-designed steel structures manufactured in factories and assembled on-site, offering cost efficiency and minimal maintenance as a building solution; they are strong, flexible in design and require minimal upkeep.

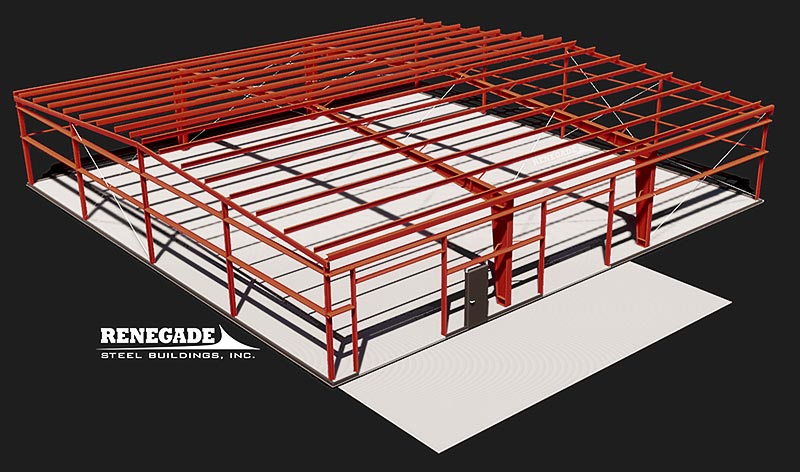

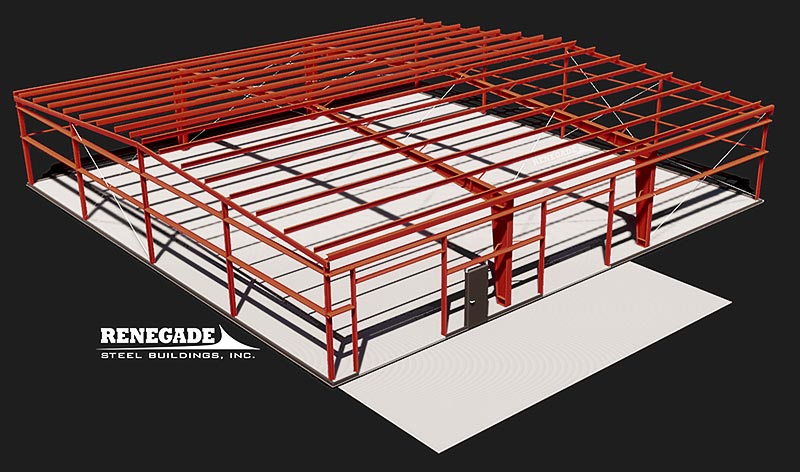

All of the parts are made ahead of time in a manufacturing facility, where every structural steel framing component, column, and wall panel is crafted to exact specifications. The pieces arrive at the construction site ready for assembly, like a well-planned puzzle that fits together perfectly.

What makes PEMB systems stand out is that they work well for many diverse businesses, from storage facilities and retail stores to churches and sports facilities. Building owners choose them because they reduce construction time by half (compared to conventional building methods), reduce waste through factory precision, and provide outstanding durability against extreme weather, fire and pests.

In this guide, you will learn what makes these pre-engineered metal buildings a smart investment for any property owner looking to build smarter and discover customization options that are offered to meet the needs of any business.

Cost Advantages

Creating pre-engineered metal buildings in a manufacturing facility cuts costs in multiple ways. The controlled environment allows precise material measurements and cuts, reducing waste compared to conventional building methods.

Labor costs drop significantly because specialized teams assemble PEMB components instead of building from scratch. Steel buildings also require little to no maintenance - their structural steel is coated with high-quality finishes that resist corrosion and rust, helping owners save money over time.

Time-Saving Construction

Durability Features

Essential Components and Design Options

Primary Structure Elements

Pre-engineered metal buildings (PEMB) rely on three fundamental structural components that work together to create strong, reliable structures:

- The main frame systems, using structural steel framing, form the building's backbone with rigid steel columns and rafters that provide the primary support. These frames effectively transfer loads from roof to foundation.

- Secondary members include purlins and girts, which connect to the main frames and support the exterior wall panels.

- The roof panels and wall panels complete the structure's envelope and can include insulation based on environmental needs.

Design Configurations

PEMB systems offer three main design layouts to match different functional requirements:

- Clear span designs create a column-free interior, providing unobstructed floor space perfect for warehouses and aircraft hangars.

- Single slope configurations work well for additions or buildings that need specific drainage patterns, commonly used in retail stores and auto shops.

- Multi-span layouts incorporate interior support columns, making them suitable for larger structures like manufacturing facilities or distribution centers where interior columns won't interfere with operations.

Customization Possibilities

Applications Across Industries

Commercial Uses

PEMBs excel in commercial applications, offering adaptable spaces that work for various business needs. Warehouses benefit from the column-free interior designs that allow large storage space and easy movement of inventory.

Retail stores take advantage of quick construction time and design flexibility that accommodate everything from small shops to large showrooms. Office buildings utilize PEMBs for their cost efficiency and ability to create professional-looking exteriors with modern finishes.

Industrial Applications

Community Spaces

Sports facilities built with PEMB systems offer large, open areas perfect for indoor courts, training spaces, and fitness centers. The metal buildings maintain comfortable temperatures year-round with proper insulation systems.

Churches select PEMBs for their cost savings and ability to create inviting worship spaces with high ceilings and open floor plans. Educational buildings also utilize these structures for gymnasiums, cafeterias, and multipurpose rooms, taking advantage of their minimal maintenance.

Start Building Your Steel Space Today

Ready to explore how a pre-engineered metal building can work for your project?

At Renegade Steel Buildings, we will walk you through your customization options and help design a building that meets your exact functional needs.

Contact our team for a free and quick consultation today!