Your Steel Building Specialist

50x50 Metal Buildings from Renegade

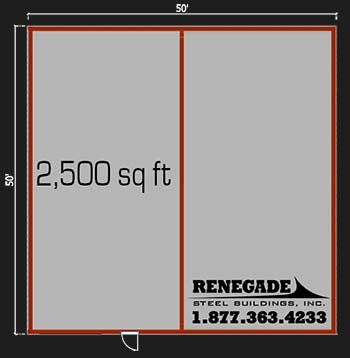

With a 50x50 steel building, you could park two cars end to end and still have room to get around them. If you used it for agricultural purposes, you would be sure to have room for all of your large equipment and implements. If you had a shop for small engine repair, you would have plenty of room for a front show room / parts counter in addition to a shop are for repairs and maintenance.

This size steel building has tons of potential with 2,500 sq ft of usable floor space, for whatever your needs are. Typically designed with 2-25' bays, you have room for additional roll up doors, walk doors and even windows if you want. You also have ample space on the end wall to have an even larger door opening to accommodate large equipment or even an airplane.

As you decide on the size you need, you will have to consider your lot size and any setback requirements as well as your space requirements. While there is no true "standard" size in a pre-engineered metal building, the 50x50 seems to be very popular.

Why Choose a 50x50 Metal Building?

A 50x50 metal building offers the perfect balance of space, strength, and affordability. With 2,500 square feet of clear-span interior, you get flexible room for storage, workshops, commercial operations, or agricultural use—without the limitations of interior columns. Steel construction provides unmatched durability, resisting fire, pests, and harsh weather while keeping maintenance costs low.

Unlike traditional wood or brick structures, a pre-engineered steel building can be customized to your exact needs with doors, windows, insulation, and interior layouts. Whether you need a reliable garage, retail space, or farm building, a 50x50 metal building from Renegade Steel delivers lasting value and versatility.

Key Benefits of a 50x50 Metal Building

- Generous Space: 2,500 sq. ft. of clear-span interior for shops, garages, storage, or commercial use.

- Durable & Long-Lasting: Steel resists fire, pests, and extreme weather conditions.

- Low Maintenance: Minimal upkeep compared to wood or traditional structures.

- Customizable Design: Choose doors, windows, insulation, and interior layouts to fit your needs.

- Cost-Effective: Competitive pricing for large, versatile spaces.

- Fast Installation: Pre-engineered design allows for quicker construction than traditional buildings.

- Versatile Uses: Perfect solution for agricultural storage, commercial facilities, Steel Garage, personal workshops, vehicle garage, or retail spaces

Popular Uses for 50x50 Steel Structures

- Shops & Garages

- Agricultural Storage

- Commercial Steel Building

- Retail Space

- Personal Workshops

- Equipment Storage

- Vehicle Storage

- Commercial Building

- Metal Garage

- Industrial Buildings

- Retail Store

- Office Space

Cost of a 50x50 Metal Building

What's included in a 50x50 building package?

- Steel Framing

- I-beam main frame columns

- I-beam main frame rafters (typically clearspan unless otherwise requested)

- Bearing frame end walls (typical)

- Zee girts and purlins

- Formed base trim

- Cee channel jambs and headers for specified framed openings

- Framed openings for overhead doors or roll-up doors (when applicable)

- Nuts, Bolts and Washers for assembly

- Roof panels (PBR typical, Standing Seam Optional)

- Walls - PBR 26-gauge panels

- Trim

- Long life panel fasteners enhance durability and finish warranty

- Walk-in Door with 8" frame (when applicable)

- Mastic and caulk

- Stamped engineered drawings

What are you responsible for?

- Verification of local code requirements along with wind and snow loads - While our software pulls up general requirements for a zip code, local municipalities can easily dictate greater load requirements. When working with customers on a nationwide basis, it is nearly impossible for us to know these requirements for any specific location.

- Local permits and inspections - Talking to your local building permit office will give you the info you need in terms of obtaining your permits to build as well as the requirements for the various inspections you may need to obtain your C.O. (certificate of occupancy)

- Concrete - A pre-engineered metal building requires a solid foundation to support the wind, snow and overall loads. We only provide the steel building kit so you will need to contract with a local company to pour your footers, piers and slab.

- Anchor bolts - Anchor bolts are part of the foundation and should be supplied by your local concrete contractor. While the structural engineer may provide the diameter of the anchor bolt, your location is what determines the length. Southern states don't have to worry about a frost line whereas norther states may see 24", 36" or even deeper frost lines. Your local codes may specify this need.

- Equipment to offload delivery truck - Your metal building package comes loaded on a flatbed semi truck. The driver has no equipment to offload your truck, so you should make arrangements to have a forklift or lull to unload.

- Labor to erect - We only sell the steel building kit - we are not general contractors and don't get involved in the labor to erect. You will need to find a local company to erect.

- Equipment for erecting - If you contract a local erecting company, they should have the equipment necessary to do so. If you are wanting to do it yourself, a variety of equipment from a forklift or lull, to ladders, drills, saws, levels and cutters may be needed.

Custom Design Options with Renegade Steel

Higher pitch roof

Colored roof panels

Roof extensions w/wo soffit panels

Gutters and downspouts

Skylights

Wall lights

Windows

Wainscot

Liner Panels

Insulation

Canopies

Vent Fan

Roll up door

Ridge Vents

Cupola

Taller eave height

What makes Renegade Different?

PBR Panels

Why it matters

Long Life Screws

Why it matters

Formed Base Trim

Why it matters

Framed Openings

Why it matters

Factory Welded Clips

Why it matters

Made in the USA - Our steel Building kits are sourced from high-quality steel in the United States, along with engineering, detailing and fabrication done right here in the good old USA!

Made in the USA - Our steel Building kits are sourced from high-quality steel in the United States, along with engineering, detailing and fabrication done right here in the good old USA! Low Maintenance - Unlike traditional building materials that require constant upkeep, steel buildings are very low maintenance.

Low Maintenance - Unlike traditional building materials that require constant upkeep, steel buildings are very low maintenance. Environmentally Sustainable - Steel is one of the most widely recycled materials in the world. Steel building kits can utilize nearly 70% recycled metals and are themselves recyclable as well.

Environmentally Sustainable - Steel is one of the most widely recycled materials in the world. Steel building kits can utilize nearly 70% recycled metals and are themselves recyclable as well. Safe and Durable - Steel is a strong product to use from the I-beam Steel frames to the secondary girts and purlins to the 26 gauge panels. Each piece of the kit combines to make a sturdy, pre-engineered structure.

Safe and Durable - Steel is a strong product to use from the I-beam Steel frames to the secondary girts and purlins to the 26 gauge panels. Each piece of the kit combines to make a sturdy, pre-engineered structure. Cost Effective - Utilization of renewable resources, reduction of waste, and quicker installation results in a prefab building that can produce a favorable return on investment sooner than traditional building materials and methods.

Cost Effective - Utilization of renewable resources, reduction of waste, and quicker installation results in a prefab building that can produce a favorable return on investment sooner than traditional building materials and methods. Good Looking - Steel buildings can be customized to obtain the look you want with a variety of options.

Good Looking - Steel buildings can be customized to obtain the look you want with a variety of options. Renegade - Experience the Renegade difference from start to finish. Call us today or fill out our quick quote form. Our experienced team is here to help you through the process with no sales pressure or tactics, just honest answers and a focus on customer service.

Renegade - Experience the Renegade difference from start to finish. Call us today or fill out our quick quote form. Our experienced team is here to help you through the process with no sales pressure or tactics, just honest answers and a focus on customer service.