Your Steel Building Specialist

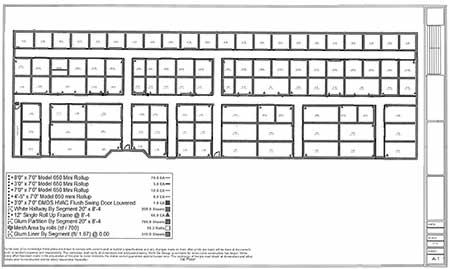

Self-storage facility in an existing building

When considering a building, there are ways to make your steel building more affordable. Part of the discussions we have with potential customers relates to how they want their building designed. While we understand the desire to have lots of roll up doors, for instance, to utilize every square foot of space in a building, it may increase your cost due to engineering requirements. With that in mind, we have 3 ways to make your steel building more affordable.

At Renegade Steel Buildings, we love to work with educated customers. We want you to be as informed as possible about the steel building purchase you are about to make. Be sure to check out some of the other informational pages we have and ask your project manager any questions you may have. We also encourage you to really check out any company you may be considering for a steel building. We’re always happy to help you make sure you’re comparing apples to apples.